Thermal transfer ribbons stand out with their versatility and cost-effectiveness. Thanks to these features, they have become an indispensable component in many industrial applications. Thermal transfer printing technology is encountered in many areas of daily life. It has a wide range of uses from bed labels, sheets, towels and clothes to car seat belt labels. In industrial environments, these ribbons are used not only in laboratory labels; they are also used in logistics processes and printed circuit boards inside household appliances.

These ribbons, which offer flexible use thanks to their resin, wax or mixture compositions, are also a perfect solution for businesses aiming for savings with their high price-performance ratio.

Many sectors, from retail to medical applications, benefit from this technology.

What is thermal transfer ribbon?

Ribbon, an important part of the thermal transfer printing process, is a plastic film coated with ink on one side and silicone on the other. Also known as TTR (thermal transfer ribbon), this film is responsible for transferring information to the printer’s printing surface. When it passes through the thermal head of the printer, it receives heat, which separates the pigment from the ribbon.

Thermal transfer ribbons have become an excellent option for the industry by offering a more durable print compared to normal ribbons. You can see a few examples below.

Pharmaceutical industry

Correct labeling of medicines is a great responsibility for manufacturers and pharmacies, because patient safety depends on it. Thermal transfer ribbons are used in the printing of drug labels, allowing the verification and recording of drug applications in healthcare institutions. They are also preferred in the printing of labels containing the batch number, production and expiration date, and supplier information on vials, ampoules, and blister packs. In addition, they play an important role in the tracking of raw materials, products, and security seals.

Thanks to their resistance to external factors, extreme temperatures, and contact with chemicals, thermal transfer ribbons both ensure compliance with legal requirements and protect patient safety.

Trade and retail

In the retail sector, labels streamline operations and eliminate the need for pre-printed or handwritten labels. It also offers great advantages in terms of security, accuracy, product tracking and overall precision. Thermal transfer ribbons are used for product identification in bakeries, stationery stores, jewelers, bookstores, supermarkets, department stores, clothing stores and many other areas.

Textile industry

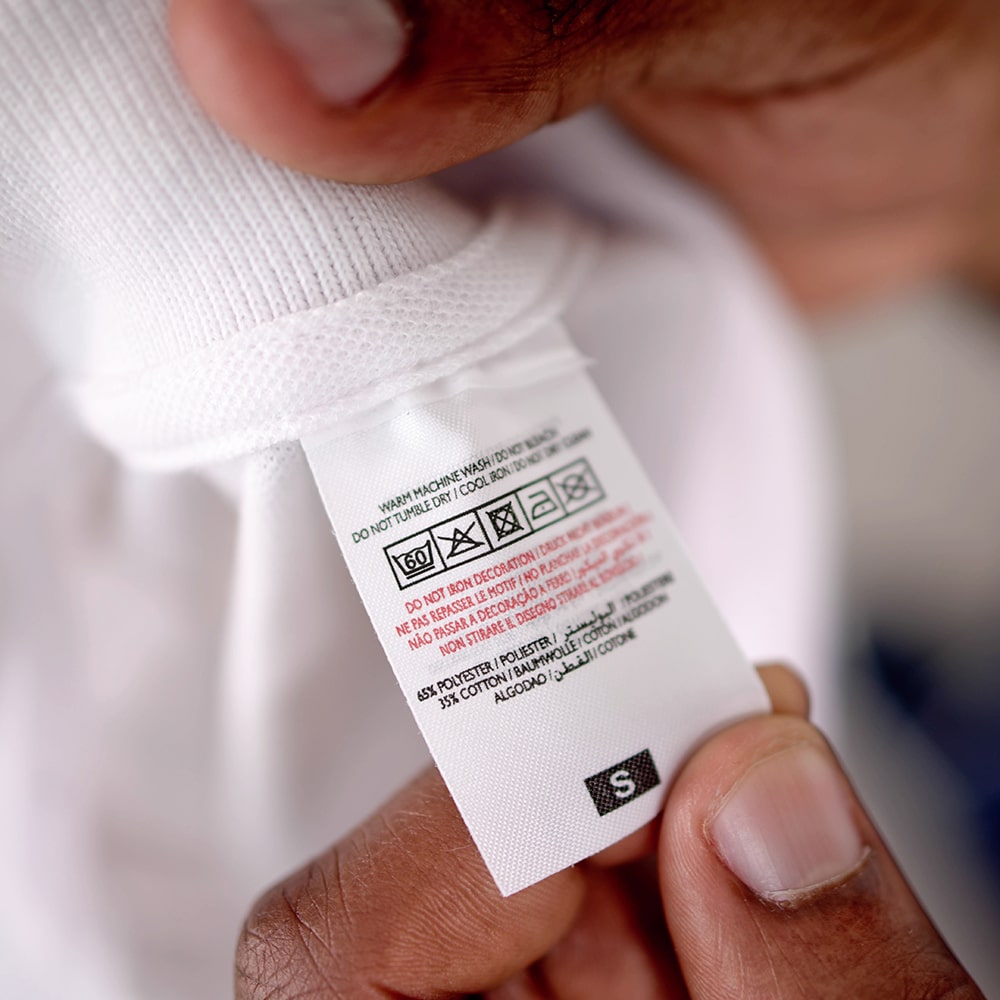

Thermal transfer ribbon technology is used to print durable identification information and care symbols for textile products. This includes labels that contain legally required data such as composition information, washing and drying instructions. In the textile industry, it is of great importance that the information on the label remains legible throughout the entire life cycle of the garment. Therefore, a reliable printing solution that can withstand external factors such as abrasion, light, temperature and solvents is required.

Automotive industry

In the automotive industry, labeling plays a critical role in the efficient procurement, identification and inventory management of components. This process is essential for the assembly and on-time delivery of cars, trucks, boats, motorcycles and other vehicles. Thermal transfer ribbons are used for labeling seat belts, batteries and brake pads, as well as in stock tracking and parts storage processes in factories.

Cosmetics

Technical information for cosmetics and personal care products should be presented to the consumer on the label as clearly and completely as possible. Beauty and personal care products such as shampoos, conditioners, lipsticks, nail polishes and lotions are just a few examples of the use of thermal transfer ribbons in this sector.

Household appliances, electronic devices and appliances

Regardless of their size or intended use, these products need to be labeled for production, component tracking, inventory, safety information and consumer education. Labels must remain legible during production, sale and use, as they fulfill many important functions. In these sectors, labels identifying voltages, electronic diagrams and important information on stoves, refrigerators and other household appliances are printed with thermal transfer ribbons.

Food industry

Unlike other sectors such as logistics, labels in the food sector must not only ensure the readability of the information, but also comply with certain standards to guarantee safety during transport and storage. Since abrasion, heat, steam and various chemicals are constantly at work in this sector, thermal transfer ribbons offer an excellent solution in this area.

In this article, we have tried to highlight the importance of ribbons in different industry segments and the following are just a few of the wide range of ribbons used.

If you are operating in the industry sector, you need reliable ribbons for your labels!

You can trust ARMOR-IIMAK for this. You can contact our team and ask us all your questions.